Our products are used in harsh and demanding environments in various vehicles and therefore need to adhere to strict quality standards. Our experienced employees and high-quality materials guarantee robust and safe products. To ensure the highest quality of our products and processes we have an ISO 9001 certified quality management system and an ISO 14001 certified environmental resource management system. We are constantly monitoring and improving our activities and the quality of our products to better meet our customers needs.

Quality

Get in touchHIGH QUALITY MATERIALS

We only use high quality materials in our products. We source our glazing elements, aluminium profiles, gaskets and glues from the top manufacturers in their respective fields. We help our customers find the most suitable options for their projects.

Our aluminium profiles are made from EN-AW 6063 alloy, which has excellent strength properties and is easy to anodize. We offer several coating options for our products.

Tempered glass is 3-5 times stronger than regular glass. When breaking, tempered glass shatters into small crumb like pieces, that wont cause cut injuries. Tempered glass is also better at withstanding impacts and temperature fluctuations than regular glass.

Laminated glass can absorb very hard impacts. The plastic film between the panes prevents the glass from shattering into pieces and instead stays in its original form if broken.

Insulated glass consists of two to three sheets of glass that are bonded together to form one uniform window element. The air trapped between the sheets acts as a great insulator.

Heated glass uses thin heating wire or a translucent metal membrane that is heated and prevents fogging.

The gaskets used between the aluminium profile and the window element is mainly EPDM-rubber or silicone. We also have EN 45545-2 certified fire resistant gaskets readily available.

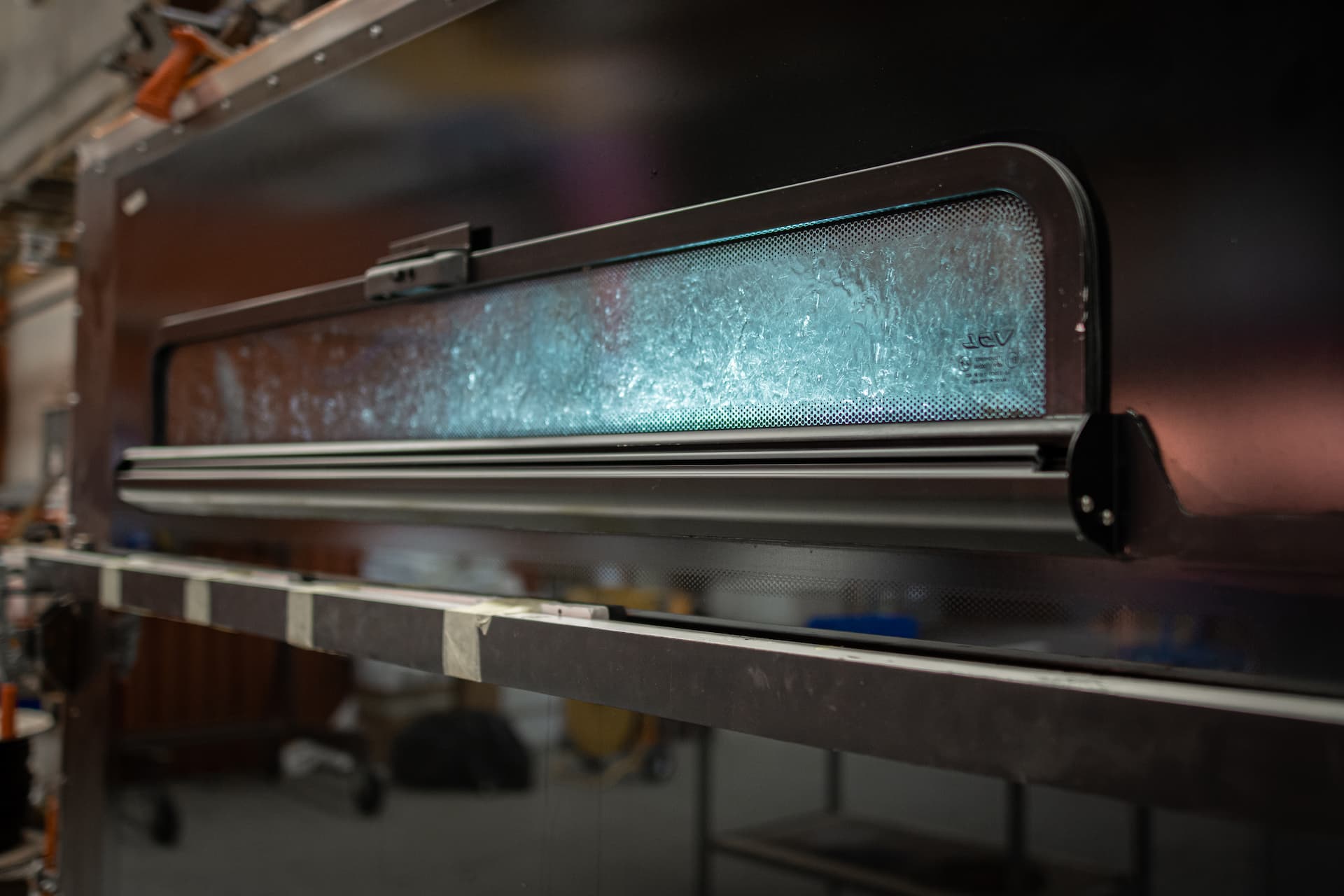

LEAK TESTING

In addition to our careful quality assurance process it is also possible to test our products for leaks. The leak resistance of our windows is tested with a custom made machine that accepts a variety of window shapes that are attached to it and sprayed with water from the inside.

The pressure of the jets is significantly higher than the pressure of naturally occurring rain. After the test is completed all the seams are checked for leaks. Our carefully designed and assembled products pass the test easily. After the product has passed the test it is dried, cleaned and packaged for transport. Our customers receive their products tested and ready for installation.